JSW-Neosteel

Pure TMT Bars

JSW Group

Amongst the leading conglomerates in India, JSW Group is a $12 billion company. It is an integral part of the O. P. Jindal Group, and has been a part of major projects that have played a key role in India’s growth.

Ranked among India’s top business houses, JSW’s innovative and sustainable ideas cater to the core sectors of Steel, Energy, Cement and Infrastructure. The Group continues to strive for excellence with its strength, differentiated product mix, state-of-the-art technology, excellence in execution and focus on sustainability.

From its humble beginnings in steel, the JSW Group has expanded its presence across India, South America, South Africa & Europe. JSW is known to be the “strategic first mover” to venture away from status quo, have the conviction to make fundamental changes and drive operational excellence on its quest to become better everyday.

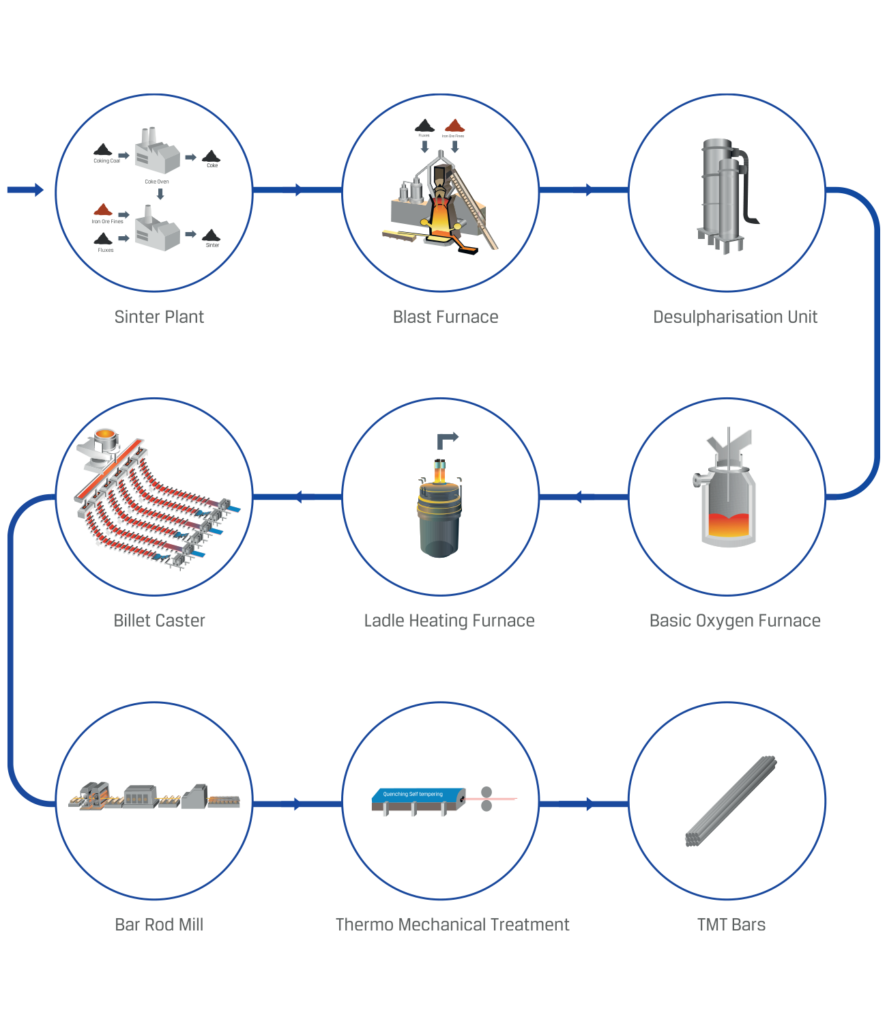

Manufacturing Process

JSW NEOSTEEL TMT bars are manufactured through primary production process to ensure purity and superior quality. The state of the art and technical advanced bar rod mills for the production are supplied by Danieli Italy and Morgan USA. JSW NEOSTEEL is toughened high strength HYOST (High Yield Quenched and Self Tempered) TMT bar conforming to IS 1788:2008. JSW NEOSTEEL bars are available in Fe500, Fe5000, Fe550D, Fe600 and CRS grades.

Process route of Blast Furnace LD Steel making – Ladle Refining – Continous Casting of billets ensures the right and desired quality with minimum tramp elements and sulphur and phosphorus content of 0.005 0.035%, Cast billets are hot rolled in state-of-the-art MORGAN and DANIELI rolling mill, which ensures uniform dimensions and properties in each bar.Sur face finish of each bar is excellent as the mill employs tungsten carbide rolls against conventional rolls. Each bar is thermomechanically treated. After leaving the last stand of the rolling mill, the bars are quenched O(rapid cooling) in water from final rolling temperature of about 1050C. The quenching is partial, only until outer surface layer has been transformed from austenite to martensite. Because of partial quenching, a part of the original heat remains in the core of the steel and on the cooling bed, this migrates towards the surface and results in an automatic self tempering process where the surface layer of martensite is tempered. The resulting tempered – martensite shows improved deformability as compared to quenched martensite.On atmospheric cooling on cooling bed. austenitic core is transformed into ductile ferrite-pearlite. The core of the heat treated bars consists of ferrite and pearlite while strong outer layer consists of martensite.

JSW Neosteel

Fe 550D Benefits

Here’s how stronger steel brings efficiency to your construction

Lower Steel Consumption

Structures designed by JSW Neosteel 550D consumes less steel, Upto 15% of steel savings.

Low Labour cost

Using less numbers of bars means using less labour which saves cost.

Cost Saving

Consumption of TMT rebars is less in Fe 550D based on the same load bearing structure.

Time Saving

Lesser time is needed for placing/tying of bars and less weight on cranes improves construction efficiency.

Strong Structure

Fe 550D based designed structure is capable to bear more load than that based on Fe 500D.

More Space

The cross-sectional area of columns made of Fe 550 TMT rebar is less than that of Fe 500D for the same load bearing design. Hence, the structure based on Fe 550D gives more carpet area.

Earthquake Resistance

Higher Strength of Fe 550D TMT provides greater protection from earthquakes.